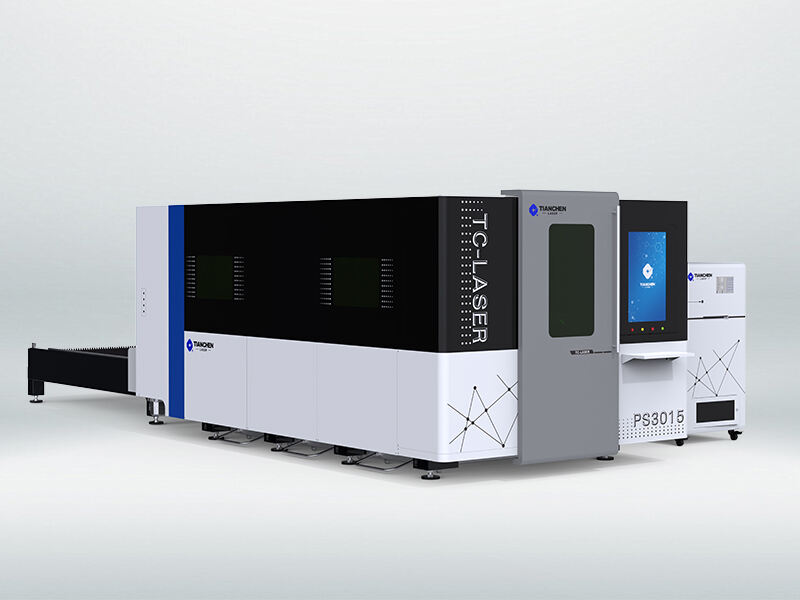

For metal cutting, the water-cooled CNC laser cutter from Tianchen Laser is the most advanced CNC Laser Cultter。As this machine is equipped with a high-end cooling system, this not only improves the cut quality of the parts, but also increases the life of the equipment and accessories. This machine also caters a broad scope of industries like automotive, aerospace and metal working industries. As you receive this product, you will get complete peace of mind as it has the newest innovation and you won’t compromise with the latest standards which means this is the best investment for any company that intends to improve their production in any way.

Copyright © 2024 by JINAN TIANCHEN LASER TECHNOLOGY CO.,LTD