Rủi laser sợi so với cắt plasma: Công nghệ nào mang lại kết quả vượt trội cho nhu cầu sản xuất của bạn?

Hiểu về các công nghệ cắt kim loại hiện đại

Sự tiến hóa của việc cắt kim loại

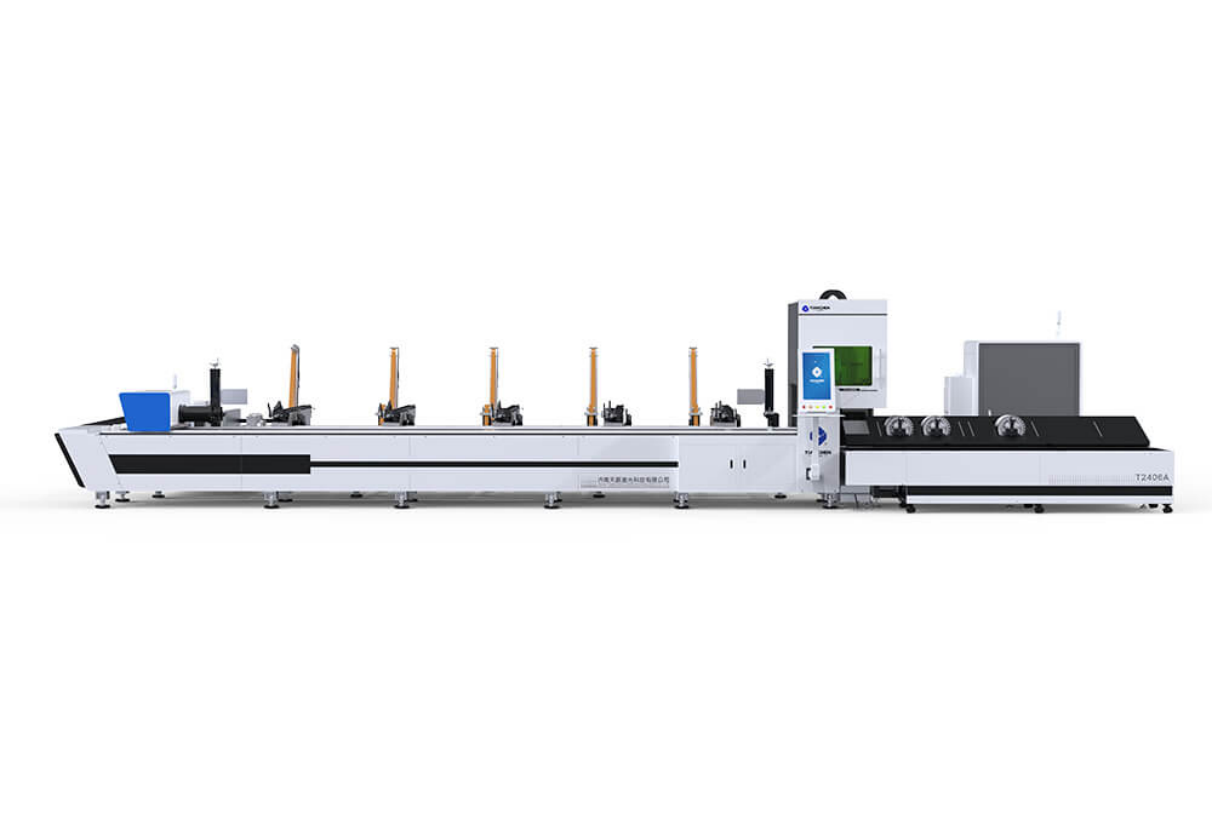

Trong bối cảnh năng động của gia công kim loại, việc chọn công nghệ cắt phù hợp ảnh hưởng đáng kể đến hiệu quả sản xuất và chất lượng sản phẩm. Là một người có kinh nghiệm trong ngành cắt laser từ năm 1995, Tianchen Laser đã chứng kiến sự chuyển mình từ các phương pháp cắt truyền thống sang công nghệ laser sợi tiên tiến. Sự tiến hóa này đã cách mạng hóa cách các nhà sản xuất tiếp cận việc chế biến kim loại.

Độ chính xác và chất lượng cạnh cao hơn

Nhận được độ chính xác vi mô

Tắt laser sợi cho thấy khả năng chính xác đáng chú ý vượt qua cắt plasma với một biên độ đáng kể. Các hệ thống laser sợi hiện đại đạt được độ chính xác định vị trong vòng micron, trong khi cắt plasma thường hoạt động với độ khoan dung rộng hơn. Độ chính xác này trở nên rất quan trọng khi sản xuất các thành phần cho các ngành công nghiệp đòi hỏi các thông số kỹ thuật chính xác, chẳng hạn như sản xuất thiết bị hàng không vũ trụ hoặc y tế.

So sánh chất lượng cạnh

Chất lượng của các cạnh cắt là một trong những sự khác biệt nổi bật nhất giữa các công nghệ này. X quang laser tạo ra các cạnh sắc nét, sạch sẽ thường không cần phải hoàn thiện thứ hai. chùm tia laser tập trung tạo ra chiều rộng cắt giảm tối thiểu, dẫn đến giảm chất thải vật liệu và khả năng chi tiết đặc biệt. Ngược lại, cắt plasma thường tạo ra các vạch rộng hơn và có thể yêu cầu các quy trình hoàn thiện bổ sung, làm tăng thời gian sản xuất và chi phí.

Tốc độ và hiệu quả xử lý

Hiệu suất cụ thể của vật liệu

Tắt laser sợi cho thấy tốc độ vượt trội, đặc biệt là với vật liệu mỏng đến trung bình. Khi chế biến thép không gỉ mỏng, hệ thống laser sợi có thể đạt tốc độ cắt nhanh hơn nhiều lần so với hệ thống plasma. Trong khi cắt plasma có thể nhanh hơn cho các vật liệu rất dày (trên 25mm), laser sợi duy trì chất lượng tốt hơn trên tất cả các phạm vi độ dày.

Các cân nhắc về hiệu quả năng lượng

Các hệ thống laser sợi hiện đại hoạt động với hiệu quả năng lượng đáng chú ý. Hiệu quả chuyển đổi điện thành quang đạt tới 30%, so với plasma điển hình 10-15%. Hiệu quả này chuyển thành chi phí hoạt động thấp hơn và giảm tác động môi trường, làm cho laser sợi là sự lựa chọn bền vững hơn cho sản xuất hiện đại.

Sự linh hoạt về vật chất và khả năng

Xây dựng các máy tính

Công nghệ laser sợi vượt trội trong chế biến các vật liệu đa dạng với độ dày khác nhau:

Xử lý thép carbon mang lại kết quả đặc biệt với các cạnh sạch và các vùng bị ảnh hưởng bởi nhiệt tối thiểu. Công nghệ xử lý các tấm mỏng đến tấm dày với chất lượng nhất quán.

Việc cắt thép không gỉ được hưởng lợi từ điều khiển nhiệt chính xác của laser sợi, ngăn chặn vật liệu bị cong và duy trì tính chất chống ăn mòn.

Xử lý nhôm đạt được kết quả vượt trội do khả năng của laser sợi để quản lý bề mặt phản xạ hiệu quả, một thách thức cho các hệ thống plasma.

Khả năng cắt đồng và đồng làm cho laser sợi khác biệt, vì plasma đấu tranh với các vật liệu dẫn điện cao này.

Chi phí hoạt động và kinh tế

Lợi ích chi phí dài hạn

Mặc dù đầu tư ban đầu vào công nghệ laser sợi có thể cao hơn, chi phí hoạt động mang lại những lợi thế hấp dẫn:

Tiêu thụ năng lượng của hệ thống laser sợi thường thấp hơn 70-80% so với các hệ thống plasma tương đương, dẫn đến tiết kiệm năng lượng đáng kể theo thời gian.

Nhu cầu bảo trì giảm đáng kể, với ít bộ phận di chuyển và vật liệu tiêu thụ cần thiết cho hoạt động liên tục.

Chi phí lao động giảm do giảm nhu cầu cho các hoạt động hoàn thiện thứ cấp và thời gian xử lý nhanh hơn.

Sự linh hoạt và tự động hóa sản xuất

Hệ thống Điều khiển Nâng cao

Hệ thống laser sợi hiện đại kết hợp các điều khiển tinh vi và khả năng tự động hóa làm tăng hiệu quả sản xuất:

Sự tích hợp của phần mềm lồng tổ tiên tiến tối đa hóa việc sử dụng vật liệu, giảm chất thải và cải thiện hiệu quả chi phí.

Khả năng điều chỉnh tham số tự động cho phép thay đổi vật liệu và độ dày nhanh chóng mà không cần sự can thiệp rộng rãi của người vận hành.

Hệ thống giám sát thời gian thực đảm bảo chất lượng nhất quán trong suốt các đợt sản xuất.

Giảm thời gian cài đặt

Hệ thống laser sợi vượt trội trong môi trường sản xuất thay đổi nhanh chóng. Công nghệ cho phép chuyển đổi nhanh chóng giữa các vật liệu và độ dày khác nhau, giảm thiểu thời gian ngừng hoạt động giữa các công việc.

Các cân nhắc về môi trường và an toàn

Cải thiện an toàn nơi làm việc

Công nghệ laser sợi tạo ra một môi trường làm việc an toàn hơn thông qua:

Môi trường cắt kín chứa khí thải và bảo vệ các nhà khai thác

Mức độ tiếng ồn giảm đáng kể so với cắt plasma

Rủi ro cháy tối thiểu do áp dụng nhiệt có kiểm soát

Giảm các vết rắc và mảnh vụn vật liệu

Tác động môi trường

Lợi ích môi trường của cắt laser sợi mở rộng ra ngoài sàn cửa hàng:

Hiệu quả năng lượng làm giảm lượng khí thải carbon tổng thể

Cắt chính xác làm giảm thiểu chất thải vật liệu

Cần nước làm mát giảm

Khí thải thấp hơn so với phương pháp cắt truyền thống

Kiểm soát chất lượng và tính nhất quán

Duy trì các tiêu chuẩn sản xuất

Tắt laser sợi cung cấp sự nhất quán đặc biệt trên các sản xuất chạy qua:

Chất lượng chùm ánh sáng ổn định trong suốt thời gian hoạt động kéo dài

Các thông số cắt liên tục bất kể khối lượng sản xuất

Hiệu suất đáng tin cậy trên tất cả các loại vật liệu

Kết quả lặp lại cho các hình học phức tạp

Phần kết luận

Những lợi thế của máy cắt laser sợi so với máy cắt plasma là đáng kể và được ghi chép rõ ràng thông qua các ứng dụng thực tế. Từ độ chính xác và chất lượng cạnh vượt trội đến chi phí vận hành thấp hơn và lợi ích môi trường, công nghệ laser sợi đại diện cho tương lai của việc cắt kim loại. Tại Tianchen Laser, ba thập kỷ kinh nghiệm của chúng tôi trong việc sản xuất hệ thống laser sợi cho phép chúng tôi cung cấp các giải pháp đáp ứng các yêu cầu công nghiệp khắt khe nhất.

Đối với các nhà sản xuất muốn tăng cường khả năng sản xuất của họ, cắt laser sợi cung cấp một sự kết hợp hấp dẫn về hiệu suất, hiệu quả và hiệu quả chi phí. Nhóm chuyên gia của chúng tôi sẵn sàng giúp bạn khám phá cách các giải pháp cắt laser sợi có thể biến đổi hoạt động sản xuất của bạn.